NITRATE

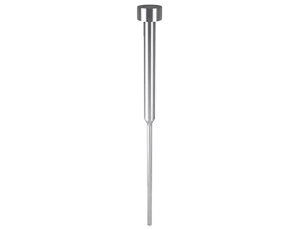

Ejector pins are vital in creating parts. They are an integral component of the ejection system in mold, which determines the final outcome of products in an injection molding process.

Injection molding is a manufacturing process that involves injecting molten plastic into a metal mold to assume the shape of the mold. Therefore, ejector pins injection molding involves the removal of completed parts from the die molds. The metal mold is made of two parts: A and B sides. Upon cooling of the molten material in the mold, both parts of the metal mold are separated to allow for the removal of the solid plastic. Injection molds are built such that when they are opened, the A-side half is lifted, leaving the formed part and the B-side.

Ejector pins are located on the B-side half of a mold, from which they push the formed part out of the mold. The pin mark of an ejector mold is commonly imprinted on finished products as a dent.