FIBROMAX®

HEAVY-DUTY NC ROTARY TABLES WITH TWIN DRIVE

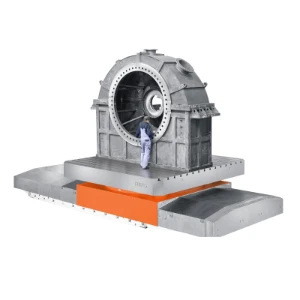

FIBROMAX 2.0 second-generation heavy-duty positioning table convinces with high rigidity and energy efficiency. With the FIBROMAX 2.0 series, FIBRO presents a completely reworked series of its high-performance XXL rotary shift tables. Compared to the first generation, the bearing diameter and thus the rigidity of the heavy-duty positioners have grown significantly – and this at virtually unchanged costs. Constantly increasing demands on the mechanical processing of complex components for wind turbines, rolling bearings, turbines, gearboxes and construction machines were the trigger for the development of this new heavy-duty concept.

THE HEAVY-LOAD POSITIONER

OUR FIBROMAX 2.0®

Read More

Read Less

APPLICATION

- Transported load over 400 tons

- Positioning as well as round and simultaneous multi-axis machining

- Available in a modular system as a stand-alone rotary table or as a turn-and-slide table

- With additional tilting axis perfect for machining wind turbine hubs

BENEFITS

- Rolling bearings for highest efficiency, minimum energy consumption and lowest heating

- Twin-Drive for highest precision and low backlash

- Power flow optimized design for highest rigidity

- Prestressed, large-dimensioned axial / radial bearing for maximum tilting rigidity as well as optimum concentricity and concentricity

- Highest geometric accuracies in the μ-range

- High-resolution rotary encoder for excellent positioning accuracy (up to ± 2 “) and repeatability (up to ± 0.25”)

- Hydraulic switch plate clamp for maximum tangential rigidity without loading the drive components

TECHNICAL HIGHLIGHTS

- Flexible positioning with an accuracy of ± 2 arc seconds

- High repeatability in terms of radial and axial concentricity in the μm range

- Absorption of radial and axial forces by preloaded, heavy-duty axial-radial bearing combination

- Increased tangential forces and reduced loads on gears through hydraulic table top clamping

- Perfectly equipped for rotary milling and simultaneous machining thanks to preloaded bearings and electrically clamped drive (twin drive)

- Different types, configuration levels and variants based on a modular design for greater flexibility

- Greater profitability from tested reliability, reduced maintenance expenses, longer service life and low energy consumption

Downloads

- No file found!